Woodworking is a craft that combines precision, skill, and creativity. At the heart of this craft lies the art of joinery—the method of connecting two pieces of wood to create a sturdy and functional structure. Understanding the various types of woodworking joints is essential for any woodworker, whether you’re a novice or a seasoned professional. This comprehensive guide delves into the most common woodworking joints, their applications, strengths, and techniques to master them.

1. Butt Joint

Definition: The butt joint is the most basic form of wood joinery, where the end of one piece of wood is butted against another piece and affixed using adhesives, nails, or screws.

Applications: Commonly used in simple frame constructions, boxes, and basic furniture where high strength isn’t a primary requirement.

Strengths and Weaknesses:

- Strengths: Easy to create; requires minimal tools and time.

- Weaknesses: Lacks mechanical strength; relies heavily on adhesives or fasteners.

Tips for a Stronger Butt Joint:

- Ensure both surfaces are smooth and square for maximum contact.

- Use high-quality wood glue and consider reinforcing with screws or dowels.

2. Mitered Butt Joint

Definition: A variation of the butt joint where the connecting ends are cut at an angle, typically 45 degrees, to form a right-angle corner.

Applications: Ideal for picture frames, decorative boxes, and trim work where aesthetics are important.

Strengths and Weaknesses:

- Strengths: Provides a clean, seamless appearance by hiding end grain.

- Weaknesses: Similar to the butt joint, it lacks inherent strength and often requires reinforcement.

Reinforcement Techniques:

- Use splines or biscuits inserted into slots cut along the mitered edges.

- Apply corner braces or specialized miter clamps during the gluing process.

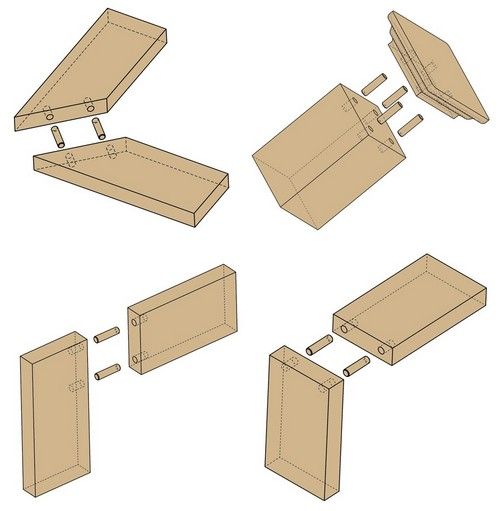

3. Dowel Joint

Definition: Involves inserting wooden dowels into corresponding holes drilled into two pieces of wood to align and strengthen the joint.

Applications: Common in furniture making, such as joining legs to tabletops or constructing frames.

Strengths and Weaknesses:

- Strengths: Provides good alignment and increased surface area for glue, resulting in a stronger joint.

- Weaknesses: Requires precise drilling; misalignment can weaken the joint.

Tips for Accurate Dowel Joints:

- Use a doweling jig to ensure precise hole placement.

- Mark corresponding dowel positions clearly on both pieces.

4. Biscuit Joint

Definition: Utilizes oval-shaped wooden biscuits inserted into slots cut into the joining pieces, which expand upon gluing to create a tight bond.

Applications: Frequently used in aligning and joining boards for tabletops, panels, and cabinets.

Strengths and Weaknesses:

- Strengths: Allows for quick alignment; provides moderate strength.

- Weaknesses: Not suitable for load-bearing joints; biscuits can swell if exposed to excessive moisture.

Best Practices:

- Ensure slots are cut precisely using a biscuit joiner.

- Select the appropriate biscuit size for the thickness of the wood.

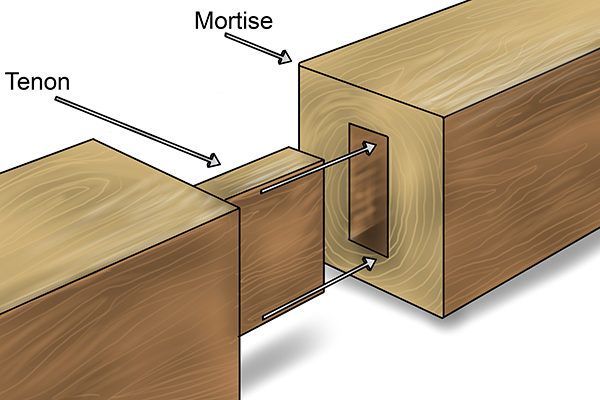

5. Mortise and Tenon Joint

Definition: A classic and robust joint where a protruding tenon on one piece fits into a corresponding mortise (hole) on another.

Applications: Widely used in frame construction, such as tables, chairs, and doors.

Strengths and Weaknesses:

- Strengths: Offers exceptional strength and durability; ideal for load-bearing structures.

- Weaknesses: More complex and time-consuming to create; requires precise cutting.

Crafting Tips:

- Use sharp chisels and saws for clean cuts.

- Dry-fit the joint before gluing to ensure a snug fit.

6. Dado Joint

Definition: A slot (dado) is cut into one piece of wood to allow another piece to fit snugly into it, typically at a 90-degree angle.

Applications: Common in shelving, cabinetry, and drawer construction.

Strengths and Weaknesses:

- Strengths: Provides substantial surface area for gluing; offers good support for shelves.

- Weaknesses: Weakens the board with the dado cut; not ideal for heavy loads without reinforcement.

Creating a Precise Dado:

- Use a dado blade on a table saw or a router with a straight bit.

- Ensure the width of the dado matches the thickness of the inserting piece for a tight fit.

7. Rabbet Joint

Definition: An L-shaped cut along the edge or end of a board allows another piece to fit into it, forming a step-like recess.

Applications: Often used in the construction of cabinet backs, drawer fronts, and window frames.

Strengths and Weaknesses:

- Strengths: Increases gluing surface area; helps with alignment during assembly.

- Weaknesses: May require additional reinforcement for heavy loads.

Tips for Cutting Rabbets:

- Employ a rabbet plane, table saw, or router for accurate cuts.

- Use a sacrificial fence to prevent tear-out when using power tools.

8. Lap Joint

Definition: Involves overlapping two pieces of wood by removing material from each so that they sit flush when joined.

Applications:

- Commonly used in framing, furniture making, and creating durable frameworks for doors and windows.

Strengths and Weaknesses:

- Strengths: Provides a larger surface area for gluing, enhancing strength. It is relatively easy to create with basic tools.

- Weaknesses: Can weaken the wood’s structural integrity if too much material is removed.

Tips for Lap Joints:

- Use a chisel or router to remove the material precisely.

- Ensure a tight fit to maximize the strength of the joint.

9. Finger Joint

Definition:

A series of interlocking fingers or slots are cut into two pieces of wood, which fit together snugly when glued.

Applications:

- Common in box construction, drawers, and decorative pieces.

Strengths and Weaknesses:

- Strengths: High strength due to the increased gluing surface; visually appealing.

- Weaknesses: Requires precise cutting; may not be suitable for heavy loads.

Tips for Crafting Finger Joints:

- Use a router with a finger joint jig for accuracy.

- Sand the fingers lightly to ensure a perfect fit without gaps.

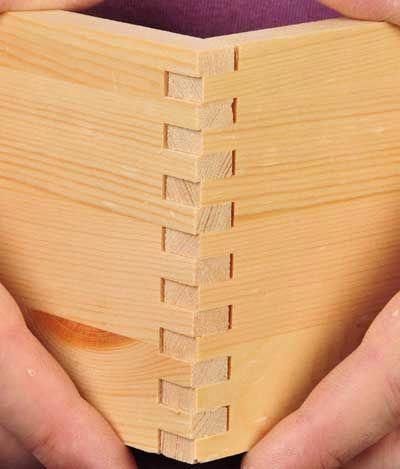

10. Dovetail Joint

Definition:

A strong, interlocking joint where a series of trapezoidal-shaped pins and tails are cut to fit together seamlessly.

Applications:

- Widely used in fine woodworking, especially for drawers, boxes, and heirloom-quality furniture.

Strengths and Weaknesses:

- Strengths: Exceptionally strong due to the interlocking design; visually stunning.

- Weaknesses: Requires significant skill and precision; time-consuming to craft by hand.

Tips for Perfect Dovetail Joints:

- Practice with scrap wood before working on the final piece.

- Use a dovetail saw and sharp chisels for clean, accurate cuts.

11. Scarf Joint

Definition:

A long, angled joint used to join two pieces of wood end-to-end, often reinforced with glue or fasteners.

Applications:

- Ideal for lengthening beams or creating decorative moldings.

Strengths and Weaknesses:

- Strengths: Maintains a seamless appearance while extending length.

- Weaknesses: Can be weaker than other joints without reinforcement.

Reinforcement Tips:

- Add screws or a dowel for additional strength.

- Apply high-quality wood glue evenly along the joint.

12. Half-Lap Joint

Definition:

Similar to the lap joint but removes half the thickness of both pieces, allowing them to sit flush when joined.

Applications:

- Common in frameworks, trellis construction, and furniture assembly.

Strengths and Weaknesses:

- Strengths: Provides good strength and alignment.

- Weaknesses: Removing too much material can weaken the wood.

Crafting Tips:

- Use a table saw or router for even material removal.

- Clamp the pieces tightly during gluing to ensure a strong bond.

13. Box Joint

Definition:

A simpler alternative to the dovetail joint, featuring square or rectangular interlocking fingers.

Applications:

- Frequently used in drawer construction and boxes.

Strengths and Weaknesses:

- Strengths: Strong and easy to make with basic tools.

- Weaknesses: Less visually striking than dovetails.

Tips for Crafting Box Joints:

- Use a jig to ensure precise spacing and alignment.

- Apply glue generously to all surfaces for maximum strength.

14. Sliding Dovetail Joint

Definition:

A variation of the dovetail joint where a dovetail-shaped groove is cut into one piece, and the mating piece slides into it.

Applications:

- Common in shelving and cabinet construction.

Strengths and Weaknesses:

- Strengths: Provides excellent mechanical strength and alignment.

- Weaknesses: Can be challenging to fit precisely.

Best Practices:

- Test-fit the joint multiple times before applying glue.

- Use a router with a dovetail bit for precise grooves.

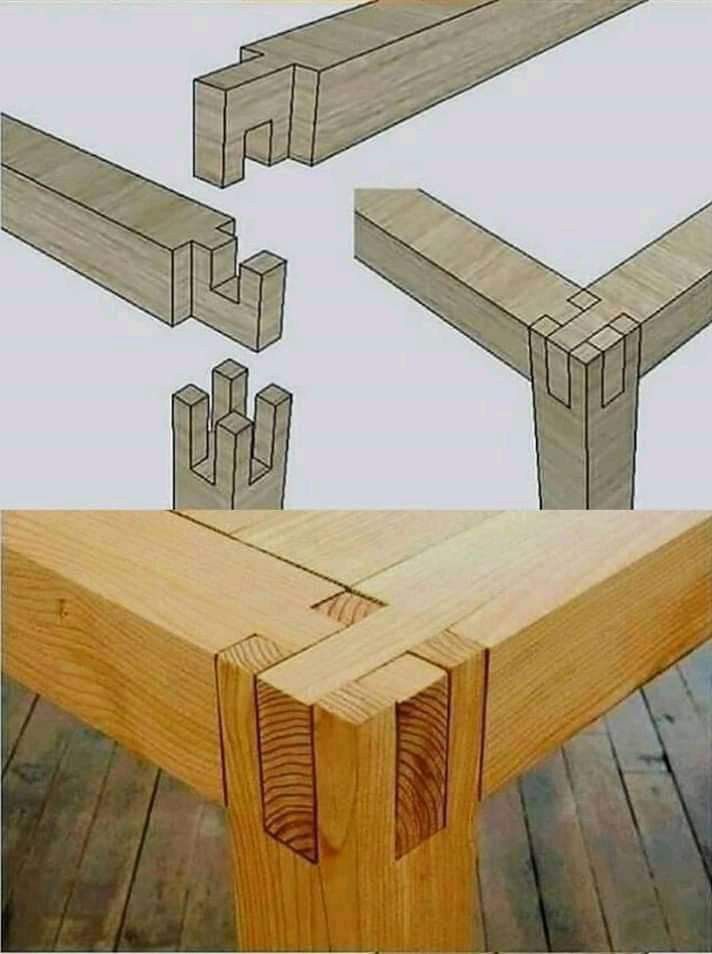

15. Bridle Joint

Definition:

Similar to the mortise and tenon joint, but instead of a hidden tenon, the entire width of the wood is cut to fit into a corresponding slot.

Applications:

- Often used in frames, gates, and chairs.

Strengths and Weaknesses:

- Strengths: Strong and easy to align; excellent for creating strong corners.

- Weaknesses: Visible joint may not be aesthetically pleasing in all designs.

Tips for Bridle Joints:

- Ensure snug fits for optimal strength.

- Reinforce with glue and clamps for additional security.

Conclusion

Mastering the various types of joints in woodwork is an essential step in becoming a skilled woodworker. Each joint serves a unique purpose, offering different levels of strength, aesthetic appeal, and functionality. By understanding and practicing these techniques, you’ll be able to create durable, beautiful projects that stand the test of time.

Start exploring these joints today, and take your woodworking skills to the next level!

Ready to take your woodworking skills to the next level? Imagine having over 16,000 detailed plans for projects just like this at your fingertips. Whether you’re a beginner or a seasoned pro, Ted’s Woodworking Plans will guide you step-by-step to create stunning pieces with ease. Don’t miss this opportunity to turn your woodworking dreams into reality.

👉 Click here to discover Ted’s Woodworking Plans today!

Discover more from WoodReality

Subscribe to get the latest posts sent to your email.