Embarking on the journey of cabinet making has been one of the most rewarding experiences in my woodworking career. Crafting custom cabinets not only enhances the functionality and aesthetics of a space but also allows for a deep expression of creativity and skill. In this comprehensive guide, I’ll share my insights and experiences to help you master the art of cabinet making.

Understanding Cabinet Making

Cabinet making is a specialized area of woodworking focused on designing and constructing storage solutions, such as cabinets, cupboards, and wardrobes. It requires a blend of precision, creativity, and technical knowledge to produce pieces that are both functional and visually appealing. Whether you’re a beginner or an experienced woodworker, the skills you develop in cabinet making can open doors to endless possibilities in your craft.

Why Cabinet Making Is Worth Learning

Cabinet making is an essential skill for anyone serious about woodworking. Here are a few reasons why it’s worth pursuing:

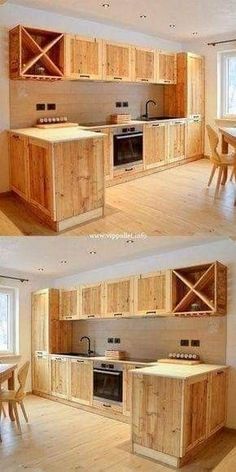

- High Demand: Custom cabinets are always in demand, whether for kitchens, bathrooms, or living spaces. Learning this craft can open up lucrative opportunities.

- Creative Expression: Cabinet making allows you to combine functionality with artistry, creating unique designs tailored to specific needs.

- Skill Expansion: Mastering cabinet making enhances your woodworking skills, from joinery techniques to finishing touches.

- Sustainability: Building your own cabinets promotes sustainability by allowing you to use high-quality, locally sourced materials and minimize waste.

Essential Tools and Materials

To begin your cabinet making journey, it’s crucial to have the right tools and materials:

- Measuring Tools: Accurate measurements are the foundation of quality cabinetry. Invest in reliable tape measures, combination squares, and marking gauges.

- Cutting Tools: A table saw is indispensable for making precise cuts. Additionally, a jigsaw and a circular saw can be useful for specific tasks.

- Joinery Tools: Chisels, doweling jigs, and biscuit joiners are essential for creating strong joints.

- Sanding and Finishing Tools: Orbital sanders and a variety of sandpapers will help achieve a smooth finish. Quality brushes and sprayers are necessary for applying stains or paints.

- Materials: Selecting the right wood is vital. Hardwoods like oak, maple, and cherry are popular choices for their durability and beauty. Plywood is often used for cabinet boxes due to its stability.

Designing Your Cabinets

The design phase is where functionality meets creativity:

- Assessing Needs: Consider the purpose of the cabinet. Is it for kitchen storage, a bathroom vanity, or a custom wardrobe? Understanding the specific needs will guide your design choices.

- Space Planning: Measure the area where the cabinet will be installed. Ensure that the dimensions align with the available space and that doors and drawers have enough clearance to open fully.

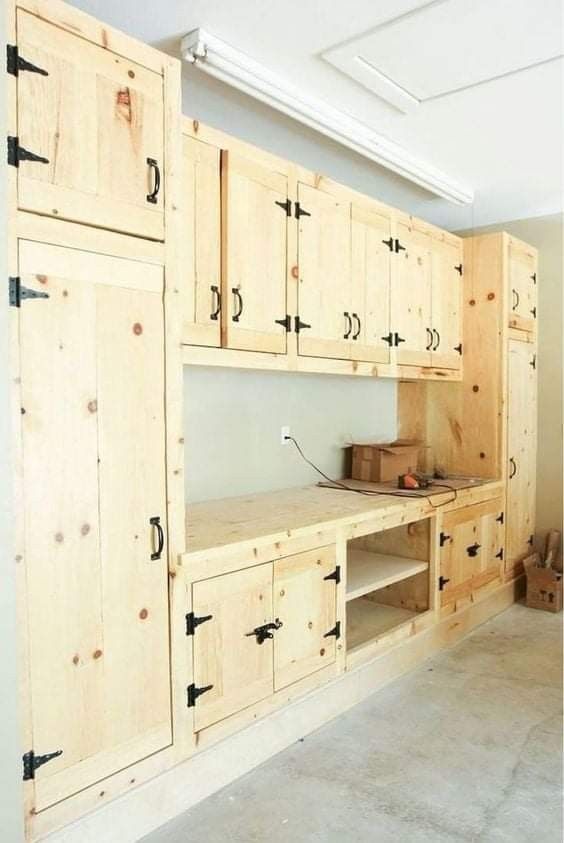

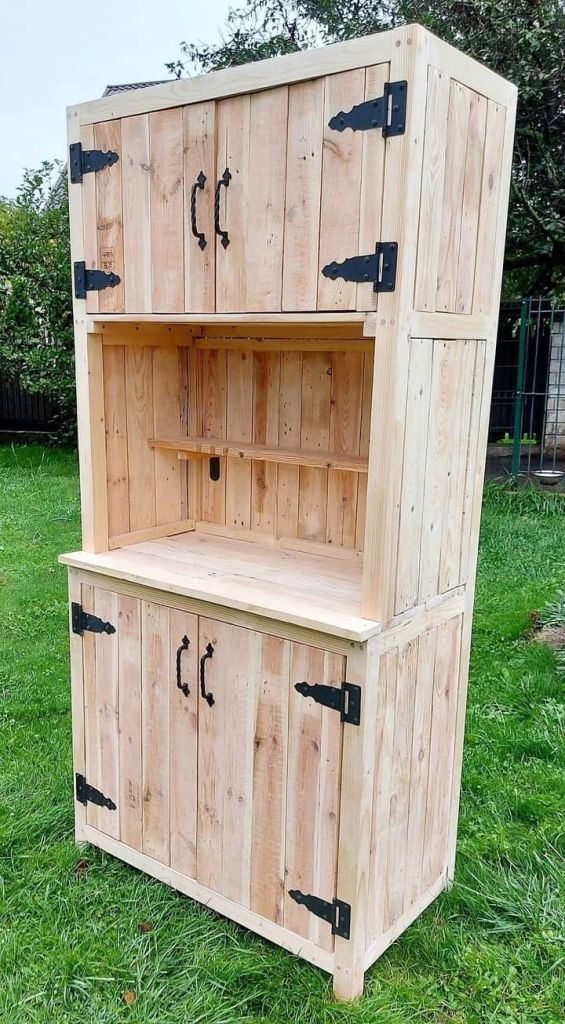

- Aesthetic Considerations: Decide on the style—modern, traditional, rustic—and choose details like door profiles, hardware, and finishes that complement the overall design.

The Process of Building a Cabinet

1. Planning and Preparation

Before you begin construction, take the time to plan your project thoroughly:

- Create a Sketch: Draw a detailed sketch of your cabinet, including dimensions, materials, and joinery methods.

- Prepare a Cut List: Make a list of all the components you’ll need, including their dimensions.

- Gather Materials: Purchase high-quality wood and hardware to ensure a durable and attractive finished product.

2. Cutting Components

Begin by cutting the sides, top, bottom, and shelves according to your measurements. Precision is key to ensuring all parts fit together seamlessly. Use a table saw for straight cuts and a jigsaw for curved or irregular shapes.

3. Assembling the Box

Use joinery techniques like dado joints or biscuits to assemble the cabinet box. Apply wood glue to the joints and secure them with clamps while the glue dries. Check that the box is square by measuring diagonals; they should be equal.

4. Adding Face Frames

If your design includes a face frame, attach it to the front of the cabinet box. This adds strength and provides a mounting surface for doors. Use pocket screws or dowels to secure the frame.

5. Constructing Doors and Drawers

Build doors and drawers to fit the openings. Pay attention to alignment and spacing to ensure smooth operation. Install hinges and drawer slides, making adjustments as needed for proper functionality.

6. Sanding and Finishing

Sand all surfaces smoothly, progressing through finer grits of sandpaper. Apply your chosen finish, whether it’s paint, stain, or a clear coat, to protect the wood and enhance its appearance. Take your time during this step to achieve a professional-looking result.

Installation

Proper installation ensures that your cabinet is functional and secure:

- Leveling: Use shims to level the cabinet, especially on uneven floors. A level cabinet prevents doors and drawers from swinging open or closed unintentionally.

- Securing to Walls: Anchor the cabinet to wall studs using appropriate screws. This provides stability and prevents tipping.

Advanced Techniques

As you gain experience, you can explore advanced techniques to enhance your cabinets:

- Incorporating Decorative Details: Add crown molding, beveled edges, or inlays for a more sophisticated look.

- Soft-Close Mechanisms: Install soft-close hinges and drawer slides for a high-end feel.

- Custom Storage Solutions: Design features like pull-out shelves, lazy Susans, or spice racks to maximize functionality.

Tips for Success

- Plan Thoroughly: Spend ample time in the planning phase. Detailed drawings and cut lists can prevent costly mistakes.

- Invest in Quality Tools: High-quality tools may have a higher upfront cost but will pay off in accuracy and durability.

- Practice Patience: Cabinet making is intricate work. Take your time to ensure each step is completed to the best of your ability.

Common Mistakes to Avoid

Even experienced woodworkers can make mistakes. Here are a few to watch out for:

- Rushing the Process: Skipping steps or rushing can lead to errors that are difficult to fix later.

- Ignoring Grain Direction: Always pay attention to the wood grain when cutting and assembling components.

- Using Inferior Materials: Cheap materials may save money upfront but can compromise the quality and longevity of your cabinets.

Expanding Your Skills

To further enhance your cabinet making skills, consider exploring comprehensive resources like Ted’s Woodworking Plans. This collection offers detailed plans and step-by-step instructions for a variety of woodworking projects, including cabinets. Access to such resources can provide inspiration and guidance, helping you tackle more complex designs with confidence.

Conclusion

Mastering cabinet making is a fulfilling endeavor that combines technical skill with artistic expression. By understanding the fundamentals, investing in quality tools, and dedicating time to practice, you can create custom cabinets that are both beautiful and functional. For those looking to expand their woodworking repertoire, Ted’s Woodworking Plans offers a wealth of projects to explore and master. Happy building!

Affiliate Disclosure:

This article contains affiliate links. If you click on one of these links and make a purchase, I may earn a small commission at no additional cost to you. This helps support the content I create and allows me to continue providing helpful tips and resources. Thank you for your support!

Discover more from WoodReality

Subscribe to get the latest posts sent to your email.

Pingback: DIY Woodworking Projects for Small Spaces: Maximizing Functionality with Style – WoodReality

Pingback: Finish Carpentry Techniques for Beginners: A Step-by-Step Guide – WoodReality