Introduction

Building a shed can be one of the most rewarding DIY projects for homeowners. Not only does a shed give you extra storage space, but it can also become a backyard workshop, hobby room, or even a home office. Many people build sheds to save money compared to buying a pre-made one, but here’s the catch: if you make a few simple mistakes during the process, that shed could end up costing you far more than you ever expected.

Thousands of homeowners each year waste money by building sheds that are too small, unstable, or poorly designed. Some even have to tear them down and start all over again. That’s why it’s so important to learn from others’ mistakes before you pick up your hammer.

In this detailed guide, we’ll cover the 10 most common shed building mistakes that can cost you thousands—and how to avoid them. Whether you’re a beginner DIYer or someone with experience in carpentry, these tips will help ensure your shed lasts for decades instead of falling apart in just a few years.

Mistake 1: Choosing the Wrong Location

Why It’s a Problem

The location of your shed can make or break your project. It affects drainage, stability, accessibility, and even legality. Unfortunately, many people build their sheds in spots that look convenient but turn out to be poor choices over time.

Real-Life Example

One homeowner built a shed at the bottom of his yard without realizing it was the lowest point of the property. After the first big rainstorm, the shed’s floor was underwater, and within a year the wooden structure started to rot. He ended up having to spend $2,500 to rebuild the shed in a different location.

Costly Consequences

- Flood damage from rain and groundwater.

- Wood rot and mold inside the shed.

- Legal issues if built too close to property lines.

- Trees nearby can drop heavy branches and cause roof damage.

How to Avoid It

- Check your yard’s drainage patterns after heavy rain. Pick a higher ground location.

- Leave clearance from property lines—at least 5–10 feet in most areas.

- Avoid building near trees whose roots can damage foundations.

- Think about accessibility—can you easily move lawnmowers, bikes, or large items in and out?

💡 FAQ: How far should a shed be from my house?

In most cases, at least 10 feet. This prevents moisture issues and makes fire safety inspectors happy.

Mistake 2: Ignoring Building Permits and Codes

Why It’s a Problem

Many DIY builders skip permits to save time or money. But local governments often require permits for sheds over a certain size—sometimes as small as 100 square feet. If you’re caught, you may be forced to tear down your shed completely.

Real-Life Example

A man in New Jersey built a large workshop shed without a permit. Neighbors complained, and the city ordered him to demolish it. He lost over $6,000 in materials and labor.

Costly Consequences

- Fines and legal trouble.

- Insurance won’t cover damages for unpermitted structures.

- Forced demolition or relocation.

How to Avoid It

- Call your local zoning office before starting.

- Ask about size limits and setbacks (distance from fences, property lines, and other buildings).

- Get electrical permits if you plan to run power to the shed.

💡 FAQ: Do I need a permit for a small shed?

It depends on your city. Some places don’t require one for sheds under 120 sq. ft., while others require a permit for any structure.

Mistake 3: Using the Wrong Foundation

Why It’s a Problem

The foundation is the backbone of your shed. If it’s weak, the entire structure will suffer. Placing a shed directly on soil is a recipe for sinking, shifting, and water damage.

Real-Life Example

One DIYer placed his shed on wooden skids without a gravel base. Over time, the skids absorbed water and rotted. His shed tilted sideways, and repairing the damage cost more than building a new one.

Costly Consequences

- Uneven flooring.

- Doors and windows won’t close properly.

- Moisture rots wood from the bottom up.

- Entire shed collapse if the ground shifts.

How to Avoid It

- Use gravel pads with concrete blocks for smaller sheds.

- For larger sheds, pour a concrete slab for maximum stability.

- Always check that your foundation is perfectly level before building.

💡 FAQ: What’s the cheapest shed foundation?

A gravel pad with treated 4×4 skids is affordable, durable, and beginner-friendly.

Mistake 4: Skimping on Materials

Why It’s a Problem

Everyone loves saving money, but using cheap or untreated materials guarantees future problems. Sheds face constant exposure to the elements, so durability matters.

Real-Life Example

A homeowner built his shed with regular plywood siding to save money. Within two years, it warped and rotted. Replacing it with pressure-treated siding cost him $1,200.

Costly Consequences

- Higher long-term costs from constant repairs.

- Weak structures that collapse in storms.

- Reduced resale value of your home.

How to Avoid It

- Always use pressure-treated lumber for floors and frames.

- Invest in exterior-grade siding like T1-11 or engineered wood.

- Use galvanized screws and nails to prevent rust.

💡 FAQ: Can I use pallet wood for sheds?

Yes, but only for decorative features. For structure, use treated, sturdy lumber.

Mistake 5: Poor Roofing Choices

Why It’s a Problem

The roof is your shed’s main line of defense. A weak roof means leaks, rot, and expensive repairs.

Real-Life Example

A DIY builder used roll roofing (meant for temporary sheds) on his permanent workshop. Within 18 months, leaks destroyed his tools. Replacing the roof with shingles cost $1,800.

Costly Consequences

- Leaks damage flooring, tools, and walls.

- Mold and mildew infestations.

- Higher energy costs if shed is insulated.

How to Avoid It

- Use asphalt shingles or metal roofing for long life.

- Ensure a minimum 4/12 pitch for water drainage.

- Add roof overhangs to protect siding from rain.

💡 FAQ: What’s the best roofing for a shed?

Metal roofing lasts the longest, while asphalt shingles are affordable and attractive.

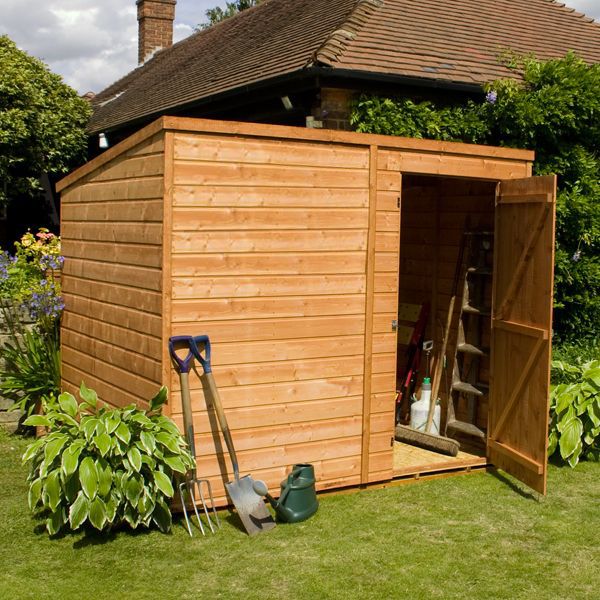

Mistake 6: Underestimating Storage and Space Needs

Why It’s a Problem

One of the biggest regrets shed owners have is building too small. What looks huge on paper feels tiny once you start filling it with tools, bikes, and seasonal storage.

Real-Life Example

A couple built a 10×10 shed for lawn tools. Within six months, it was overflowing with bikes, holiday decorations, and garden supplies. They ended up building a second shed for $2,000 instead of just making the first one bigger.

Costly Consequences

- Running out of space almost immediately.

- Needing expensive add-ons or second sheds.

- Difficulty organizing and accessing items.

How to Avoid It

- Make a list of everything you’ll store inside.

- Add 20–30% extra space for future growth.

- Use shelves, hooks, and lofts for vertical storage.

💡 FAQ: Is a 10×12 shed big enough?

It works for basic storage, but if you want a workshop, go at least 12×16.

Mistake 7: Poor Ventilation and Insulation

Why It’s a Problem

Without airflow and insulation, your shed will feel like a sauna in summer and a freezer in winter. Worse, poor ventilation causes moisture buildup, which damages wood and tools.

Real-Life Example

A DIYer built a shed for woodworking but skipped ventilation. Within a year, mold covered his walls, and $3,000 worth of tools were ruined.

Costly Consequences

- Mold, mildew, and wood rot.

- Rusted tools and damaged equipment.

- Unusable space for hobbies or office use.

How to Avoid It

- Install roof vents, ridge vents, or gable vents.

- Use foam board or fiberglass insulation if you’ll spend time inside.

- Add windows for natural airflow.

💡 FAQ: Do I need to insulate my shed?

If it’s just for storage, ventilation is enough. If you’ll work inside, insulate for comfort.

Mistake 8: Forgetting About Security

Why It’s a Problem

Sheds are prime targets for thieves. Many people store expensive tools, lawnmowers, and even ATVs inside. If your shed isn’t secure, you could lose thousands overnight.

Real-Life Example

One homeowner lost $4,500 worth of power tools when thieves pried open his weak shed door. Insurance didn’t cover it because the shed wasn’t properly secured.

Costly Consequences

- Theft of expensive equipment.

- Higher insurance premiums.

- Costly upgrades after a break-in.

How to Avoid It

- Install reinforced doors with deadbolts.

- Use motion-activated lights and cameras.

- Anchor the shed foundation to prevent forced entry.

💡 FAQ: What’s the best shed lock?

A heavy-duty padlock with a hidden shackle is harder to cut with bolt cutters.

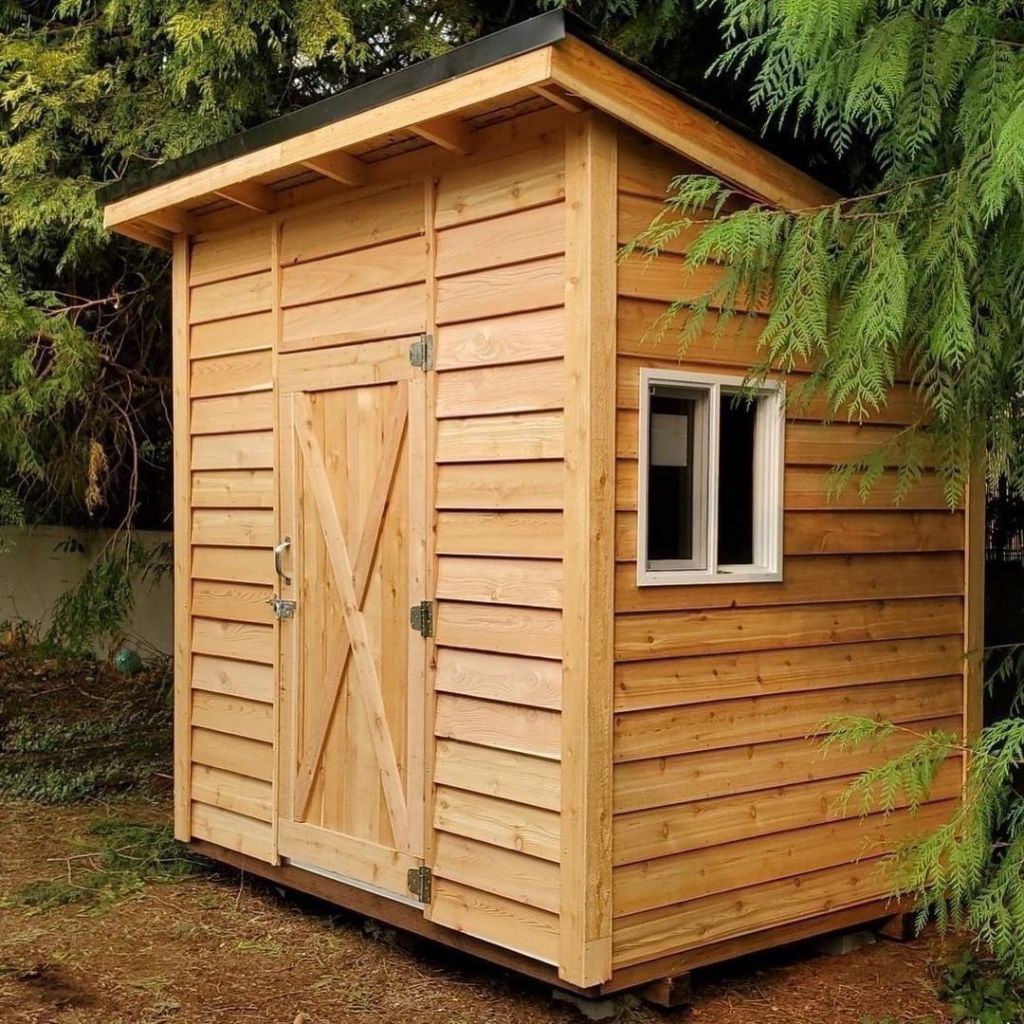

Mistake 9: Poor Planning and Design

Why It’s a Problem

Jumping into construction without a detailed plan is one of the costliest mistakes you can make. Guesswork leads to wasted cuts, weak structures, and frustration.

Real-Life Example

A beginner built his shed without plans. He miscalculated roof angles, leaving a gap that leaked every time it rained. Repairing the roof cost him another $1,000.

Costly Consequences

- Wasted lumber and materials.

- Weak or unstable shed.

- Shortened lifespan of the structure.

How to Avoid It

- Always use detailed blueprints before starting.

- Consider windows, doors, and future storage needs in your design.

- Plan for utilities (electricity, insulation) in advance.

💡 Recommended Resource: If you want professional shed designs that eliminate guesswork, check out Ryan Shed Plans. It includes 12,000+ step-by-step plans with diagrams, cutting lists, and material guides. Using ready-made plans prevents costly mistakes.

Mistake 10: Not Budgeting Properly

Why It’s a Problem

A shed project often goes over budget because people forget to account for hardware, paint, roofing, and finishing touches. Running out of money mid-project leads to cheap shortcuts that reduce the shed’s lifespan.

Real-Life Example

A homeowner budgeted $1,500 for his shed but didn’t factor in shingles, paint, or insulation. He ended up spending $2,700—almost double.

Costly Consequences

- Incomplete projects.

- Cutting corners with low-quality materials.

- Delays that lead to weather damage during construction.

How to Avoid It

- Make a full material list before buying anything.

- Add 15% extra for unexpected expenses.

- Prioritize structure and foundation before cosmetic upgrades.

💡 FAQ: How much does a 12×16 shed cost to build?

DIY costs range from $2,500–$5,000 depending on materials. Pre-built kits are usually more expensive.

Conclusion

Building a shed can save you money and add incredible value to your home—but only if you do it right. From choosing the wrong location to skipping ventilation, these 10 mistakes have cost homeowners thousands of dollars in repairs and rebuilds.

The good news is, with the right preparation, you can avoid these problems entirely. Start with a solid plan, use quality materials, and think about the long-term function of your shed.

💡 Pro Tip: If you want to build your shed with confidence, grab Ryan Shed Plans. With 12,000+ professional blueprints, you’ll avoid costly errors and build a shed that lasts for decades.

Affiliate Disclosure

This article contains affiliate links. If you click a link and make a purchase, I may earn a small commission at no additional cost to you. I only recommend products and plans that I believe provide genuine value to readers.

Discover more from WoodReality

Subscribe to get the latest posts sent to your email.