In the dynamic world of woodworking, one ancient craft is experiencing a remarkable resurgence in 2025: Japanese joinery. Renowned for its precision, durability, and aesthetic elegance, this traditional technique is captivating woodworkers, architects, and DIY enthusiasts worldwide. By creating strong, nail-free joints that interlock like a puzzle, Japanese joinery blends functionality, artistry, and sustainability. This guide explores why Japanese joinery is dominating woodworking in 2025, covering its history, techniques, tools, applications, and modern relevance. Whether you’re a seasoned craftsman or a beginner, this article will inspire you to embrace this timeless art and elevate your woodworking projects.

Table of Contents

- Introduction to Japanese Joinery

- The Historical Roots of Japanese Joinery

- Why Japanese Joinery Is Trending in 2025

- Key Techniques of Japanese Joinery

- Essential Tools for Japanese Joinery

- Applications in Modern Woodworking

- Sustainability and Japanese Joinery

- Learning Japanese Joinery: Tips for Beginners

- Challenges and Considerations

- The Future of Japanese Joinery

- Conclusion

- Affiliate Disclosure

Introduction to Japanese Joinery

Japanese joinery, often referred to as kumi tsugi (wood joining), is a centuries-old woodworking technique that creates robust, durable structures without nails, screws, or adhesives. Instead, it relies on precisely crafted interlocking joints that fit together seamlessly, leveraging the natural strength and flexibility of wood. From ancient temples like Horyu-ji in Nara to modern furniture and architecture, Japanese joinery showcases a perfect balance of form and function.In 2025, Japanese joinery is gaining global popularity for several compelling reasons:

- Aesthetic Elegance: Intricate joints, such as dovetails and mortise-and-tenon, are visually stunning, adding sophistication to any project.

- Sustainability: By avoiding metal fasteners and glue, it aligns with eco-conscious building trends.

- Durability: Structures like the 7th-century Horyu-ji Temple demonstrate longevity, even in earthquake-prone regions.

- Cultural Appeal: A growing appreciation for artisanal craftsmanship and Japanese aesthetics is driving interest among modern woodworkers.

This article delves into why Japanese joinery is reshaping woodworking in 2025, offering practical insights for incorporating these techniques into your projects, whether you’re building furniture, structures, or decorative pieces.

The Historical Roots of Japanese Joinery

Japanese joinery originated in the 7th century, influenced by Chinese woodworking techniques introduced during the spread of Buddhism to Japan. Iconic structures like Horyu-ji Temple, built in 607 CE and now a UNESCO World Heritage Site, showcase early examples of these methods, with wooden frameworks that have endured for over a millennium. Over time, Japanese artisans refined these techniques, developing a distinctive style that prioritized precision, durability, and harmony with nature.Key Historical Influences

- Buddhist Architecture: The need for earthquake-resistant temples drove the development of flexible, interlocking joints that could withstand seismic activity.

- Resource Scarcity: Japan’s limited supply of high-quality iron meant early nails were brittle and prone to rust, leading to nail-free construction methods.

- Wabi-Sabi Philosophy: This Japanese aesthetic, which values simplicity and imperfection, shaped the elegant yet functional designs of joinery.

By the 12th century, Japanese joinery had evolved into a sophisticated craft, used in temples, shrines, castles, and furniture. The miya daiku (temple carpenters) became revered artisans, passing their expertise through generations via apprenticeships. This rich history continues to inspire modern woodworkers, who are rediscovering the beauty and practicality of Japanese joinery in 2025.

Why Japanese Joinery Is Trending in 2025

Several factors are propelling Japanese joinery to the forefront of woodworking in 2025, making it a preferred choice for professionals and hobbyists alike:

Sustainability and Eco-Friendly Design

As environmental concerns grow, Japanese joinery’s reliance on wood—a renewable resource—and avoidance of metal fasteners or adhesives resonates with eco-conscious builders. Unlike concrete or steel, which have significant carbon footprints, wood-based joinery minimizes waste and environmental impact, aligning with global sustainability goals.

Aesthetic Appeal

The intricate joints of Japanese joinery, such as the kawai tsugi or kanawa tsugi, are not only functional but also visually captivating. Exposed joints in furniture or architecture serve as decorative elements, complementing the minimalist and artisanal design trends of 2025.

Durability and Earthquake Resistance

Japan’s frequent earthquakes necessitated flexible, resilient structures. Interlocking joints allow buildings to flex during seismic activity, reducing the risk of collapse. This durability, proven by structures like Horyu-ji, makes Japanese joinery a valuable technique for modern, earthquake-resistant designs.

Technological Integration

Advancements in technology, such as CNC machines and software like the Tsugite program from Tokyo University, are making Japanese joinery more accessible. These tools enable precise cutting of complex joints, bridging traditional craftsmanship with modern efficiency.

Cultural Appreciation

The global fascination with Japanese culture—evident in trends like sushi, bonsai, and minimalism—extends to woodworking. Social media platforms like Instagram and YouTube amplify this trend, with artisans like Dylan Iwakuni showcasing intricate joints to millions, inspiring woodworkers worldwide.

Craftsmanship Renaissance

In an age of mass-produced goods, there’s a renewed appreciation for handmade, high-quality craftsmanship. Japanese joinery, requiring years of skill to master, embodies this return to artisanal values, appealing to those seeking unique, durable creations.

Key Techniques of Japanese Joinery

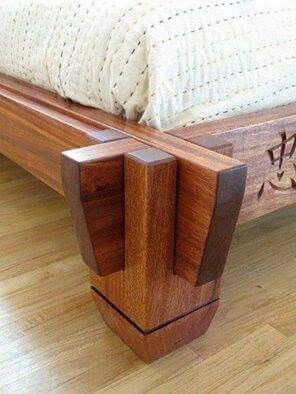

Japanese joinery encompasses a wide range of joints, each designed for specific structural or aesthetic purposes. Below are some of the most iconic techniques, complete with their applications and benefits:

Kanawa Tsugi

The kanawa tsugi is a half-blind tenoned, dadoed, and rabbeted scarf joint used to connect beams end-to-end, commonly found in roof beams, bridges, and temples.

- How It Works: One piece features a tenon and dado, while the other has a matching rabbet and groove, creating a seamless, strong connection.

- Pros: Exceptional strength with minimal visible joint lines, ideal for structural applications.

- Cons: Requires precise measurements and advanced skill to execute.

Shikuchi

The shikuchi is a sliding dovetail joint, where one piece fits into a groove on another, providing superior stability for furniture and shelving.

- How It Works: A dovetail-shaped tenon slides into a corresponding groove, locking securely without fasteners.

- Pros: Resists lateral forces, making it ideal for drawers and shelves.

- Cons: Time-consuming to craft with precision.

Kumi Ikigumi

This technique involves interlocking wooden beams to create frameworks without nails, often used in temples and shrines for structural integrity and aesthetic appeal.

- How It Works: Beams are cut with interlocking notches that fit tightly, relying on compression for strength.

- Pros: Flexible for earthquake-prone areas, visually striking.

- Cons: Demands high skill and precise measurements.

Kumiko

Kumiko is a decorative woodworking technique that uses small, intricately arranged wooden strips to create geometric patterns, often seen in shoji screens or sliding doors.

- How It Works: Thin wooden strips are cut and fitted into complex patterns without glue, relying on precise fits for stability.

- Pros: Adds artistic flair to functional pieces like screens or panels.

- Cons: Extremely labor-intensive and requires advanced craftsmanship.

Hozo (Mortise and Tenon)

The hozo is a classic mortise-and-tenon joint, where a tenon on one piece fits into a mortise on another, widely used in furniture and structural frameworks.

- How It Works: The tenon is shaped to fit snugly into the mortise, often secured by the wood’s natural compression.

- Pros: Versatile, strong, and suitable for beginners.

- Cons: Requires precise cutting for a tight, secure fit.

For woodworkers eager to master these techniques, resources like Ted’s Woodworking Plans provide detailed blueprints and step-by-step guides for incorporating Japanese joinery into furniture, sheds, and other projects, making it accessible for all skill levels.

Essential Tools for Japanese Joinery

Japanese joinery demands specialized tools designed for precision and handwork, distinguishing it from Western woodworking’s reliance on power tools. Below are the essential tools for practicing Japanese joinery, along with tips for their use:

Japanese Hand Saws (Nokogiri)

Japanese saws cut on the pull stroke, offering superior control and precision compared to push-stroke Western saws.

- Types:

- Ryoba: Double-edged saw for rip and crosscuts, versatile for general woodworking.

- Dozuki: Fine-toothed saw for precise joinery cuts, ideal for tenons and dovetails.

- Tip: Use a light touch and let the saw do the work to avoid bending the thin blade.

Chisels (Nomi)

Japanese chisels are renowned for their sharpness and durability, featuring laminated steel blades that hold an edge longer.

- Types:

- Hiranomi: Flat chisels for general work, such as carving mortises.

- Tsukinomi: Paring chisels for fine, detailed work on joints.

- Tip: Sharpen chisels regularly with waterstones to maintain clean, precise cuts.

Planes (Kanna)

Japanese planes, used on the pull stroke, create smooth surfaces for tight-fitting joints.

- Types:

- Hirakanna: Smoothing planes for finishing surfaces.

- Arashiko: Jointing planes for flattening and squaring wood.

- Tip: Tune planes frequently and adjust the blade for thin shavings to achieve a polished finish.

Marking Tools

Accurate layout is critical for Japanese joinery. Tools like marking gauges (kebiki) and story sticks ensure precise measurements for joints.

- Tip: Double-check measurements before cutting to avoid costly mistakes.

Sharpening Stones

Waterstones are essential for maintaining the razor-sharp edges of Japanese tools, crucial for clean, precise cuts.

- Tip: Use a progression of grits (e.g., 800, 2000, 6000) for optimal sharpening results.

For beginners looking to build their tool collection, Ted’s Woodworking Plans offers guidance on selecting the right tools and applying Japanese joinery techniques to a variety of projects, from small boxes to large furniture pieces.

Applications in Modern Woodworking

Japanese joinery is finding diverse applications in 2025, bridging traditional craftsmanship with contemporary design:

Furniture Making

The precision of kumiko and hozo joints elevates furniture, from minimalist coffee tables to intricate cabinets. The airtight fit of sashimono (furniture joinery) creates refined, durable pieces that stand out in modern interiors.

Architecture

Architects like Kengo Kuma are incorporating Japanese joinery into modern buildings, using prefabricated wooden components and pin joints for both aesthetic and structural benefits. These techniques are ideal for sustainable, earthquake-resistant designs.

Home Renovations

Homeowners are adopting Japanese joinery for renovations, such as shoji screens, custom shelving, or exposed beam frameworks, blending tradition with modern aesthetics.

DIY Projects

DIY enthusiasts are using Japanese joinery for small-scale projects like jewelry boxes, lamps, or garden trellises. Online tutorials and resources like Ted’s Woodworking Plans make these projects accessible to hobbyists.

Sustainable Construction

Japanese joinery’s minimal waste and reliance on renewable wood make it a cornerstone of eco-friendly homes, commercial spaces, and community projects.

Sustainability and Japanese Joinery

In 2025, sustainability is a key driver of woodworking trends, and Japanese joinery aligns seamlessly with eco-conscious principles:

- Zero-Waste Design: Precise cuts minimize material waste, reducing the environmental impact of projects.

- Renewable Materials: By using only wood, Japanese joinery avoids the carbon-heavy production of metal fasteners or adhesives.

- Longevity: Structures built with Japanese joinery, like ancient temples, last centuries, reducing the need for replacements.

- Reparability: Interlocking joints can be disassembled and repaired, extending a structure’s lifespan.

This eco-friendly approach appeals to woodworkers, architects, and homeowners committed to sustainable practices, positioning Japanese joinery as a leader in green woodworking.

Learning Japanese Joinery: Tips for Beginners

Starting with Japanese joinery can be challenging, but these tips will set you on the path to success:

Start with Simple Joints

Begin with basic joints like the hozo (mortise and tenon) to build confidence before attempting complex ones like kawai tsugi.

Invest in Quality Tools

Purchase a few high-quality Japanese hand tools, such as a dozuki saw and nomi chisel, and learn to maintain them properly.

Practice Precision

Japanese joinery relies on meticulous measurements and cuts. Practice on scrap wood and use marking gauges to ensure accuracy.

Study Resources

Online courses, YouTube tutorials (e.g., Dylan Iwakuni’s channel), and plans from Ted’s Woodworking offer step-by-step guidance for beginners.

Join a Community

Engage with online communities like r/JapaneseWoodworking or local woodworking groups to share tips, ask questions, and find inspiration from artisans like Brian Holcombe.

Challenges and Considerations

While Japanese joinery is rewarding, it presents several challenges:

- Time-Intensive: Crafting joints like kumiko or kanawa tsugi can take hours or days, requiring patience.

- Skill Level: Achieving precision demands practice and experience, though beginners can start with simpler joints.

- Tool Costs: High-quality Japanese tools can be expensive, though they’re a worthwhile investment for long-term use.

- Material Selection: Softwoods used in sashimono require careful handling to avoid damage during joinery.

Despite these hurdles, the results—durable, beautiful, and sustainable creations—are well worth the effort for dedicated woodworkers.

The Future of Japanese Joinery

In 2025, Japanese joinery is poised for continued growth and innovation:

- Technological Advancements: CNC machines and software like Tsugite are making complex joints more accessible, enabling woodworkers to combine tradition with modern tools.

- Global Adoption: From North America to Europe, woodworkers are embracing Japanese techniques, inspired by social media and online education.

- Sustainable Architecture: As eco-friendly construction gains momentum, Japanese joinery’s zero-waste approach will shape modern buildings and homes.

- Cultural Preservation: Efforts to train new miya daiku and document traditional techniques ensure this craft endures for future generations.

Conclusion

Japanese joinery is transforming woodworking in 2025, offering a perfect blend of tradition, precision, and sustainability. Its nail-free, interlocking joints deliver unmatched durability and aesthetic appeal, making it ideal for furniture, architecture, and DIY projects. As woodworkers and architects embrace eco-conscious practices and seek to elevate their craft, Japanese joinery provides a timeless solution that bridges the past and future.

Whether you’re crafting a minimalist table, a garden structure, or a sustainable home, incorporating Japanese joinery can elevate your work to new heights. Resources like Ted’s Woodworking Plans offer thousands of detailed plans, including projects inspired by Japanese joinery, to guide you step-by-step. Embrace this ancient craft and discover why Japanese joinery is leading the woodworking revolution in 2025.

Affiliate Disclosure

This article contains affiliate links, including links to Ted’s Woodworking Plans. If you make a purchase through these links, we may earn a small commission at no additional cost to you. This helps support our site and allows us to continue providing valuable content. Thank you for your support!

Discover more from WoodReality

Subscribe to get the latest posts sent to your email.